|

. |

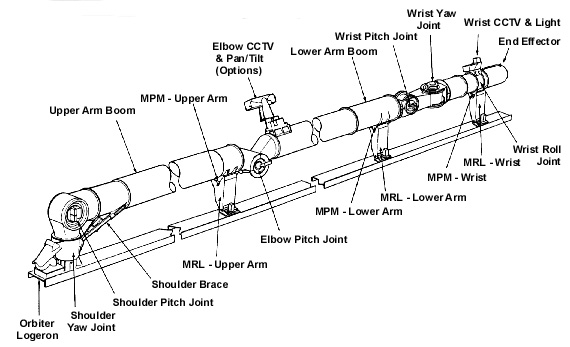

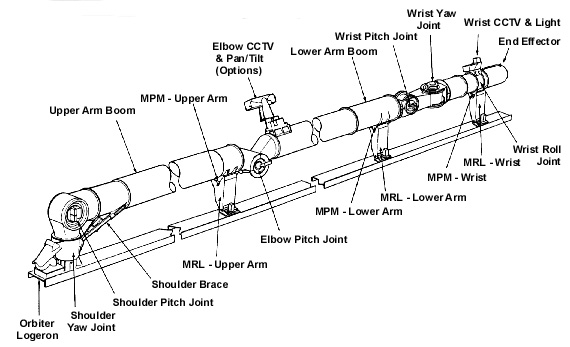

| The Canadarm's mechanical parts (Spar) |

BACKGROUND TO THE CANADARM

The Shuttle Remote Manipulator System (SRMS) or Canadarm was a joint venture between the governments of the United States and Canada to supply the NASA Space Shuttle program with a robotic arm for the deployment/retrieval of space hardware from the payload bay of the orbiter. Spar was appointed the prime subcontractor to the National Research Council of Canada, now the Canadian Space Agency, in July of 1975 for the Design Development Testing and Evaluation (DDT&E) of the manipulator arm system which was to be supplied to NASA by the Canadian government. Work began on the program in 1975 and in April 1981 the first SRMS was delivered to NASA at a cost of approximately $108 million to the Canadian government. The first flight of the SRMS was later that year - November 12, 1981. NASA subsequently ordered 4 additional Canadarm’s, one of which was lost in the Challenger accident.

GENERAL INFORMATION ON THE SHUTTLE REMOTE MANIPULATOR SYSTEM

The SRMS is a robotic arm consisting of a shoulder, elbow and wrist joint separated by an upper and lower arm boom giving it a total of six degrees-of-freedom (shoulder pitch and yaw, elbow pitch and wrist pitch yaw and roll). At a total weight of approximately 431 kg, the Canadarm is capable of manoeuvring payloads of up to 14,515 kg at a rate of .06 m/sec with a maximum contingency operation payload weight of 265,810 kg. Under unloaded conditions the SRMS can achieve a maximum translational rate of 0.6 m/sec. Ironically, the SRMS is incapable of supporting its own weight here on earth and it must be supported by specialized ground handling equipment during its acceptance testing and shipment. Although the SRMS can handle very heavy payloads, movement of the tip is very accurately controlled, allowing precise handling of delicate payloads. The length of the Canadarm is approximately 15 m and a computerized control system can be used to deploy payloads to a positional accuracy of +/- 2.0-in and +/- 1.0-degree of a pre-programmed target zone at the aforementioned rates and load conditions. The SRMS may also be operated manually by the astronauts to the same accuracy with the use of hand controllers and closed circuit televisions (CCTV) mounted on the manipulator arm. The SRMS was designed to have a life of ten years or 100 missions. STS-91 marks Canadarm’s 50th mission and an impressive performance record.

DESCRIPTION OF THE SHUTTLE REMOTE MANIPULATOR SYSTEM

The SRMS is a remotely controlled six degree-of-freedom payload handling device comprised of the following component sub-systems:

. The Canadarm's joints (Spar) JOINTS

Each subassembly component of the SRMS, for example the shoulder, elbow or wrist is made up of a basic element called a joint one-degree-of-freedom or JOD. The JOD's are simply motor driven gearboxes that allow the basic structure of the arm to articulate much like the human arm. There are two JOD's in the shoulder joint which allow the whole arm to pitch (up and down motion) and yaw (side to side motion). One in the elbow joint to allow the lower arm to pitch and three in the wrist joint to allow the tip of the arm to pitch, yaw and roll (rotating motion). SRMS is much more articulate than even the human arm and can therefore accomplish very complex manoeuvres. The JOD motors are equipped with their own brakes and joint motor speed control. Each JOD also incorporates a device called an encoder, which accurately measures joint angles. Thus each joint is capable of moving independently at different speeds and in different directions with respect to any or all the other JOD's.

BOOMS

Linking the shoulder, elbow and wrist joints are the upper and lower arm booms. These booms are constructed of graphite-epoxy. The upper arm boom is approximately 5 m long by 33 cm in diameter comprising of 16 plies of graphite-epoxy (each ply is .013 cm thick) for a total weight of just under 23 kg. The lower arm boom is approximately 5.8 m long by 33 cm in diameter comprising of 11 plies of graphite-epoxy for a total weight of just over 22.7 kg. Each boom is protected with a Kevlar bumper (the same material used in bulletproof vests) to preclude the possibility of dents or scratches on the carbon composite.

. The skeleton of the Canadarm (NASA) WIRING HARNESS

Just as the arm booms linked the shoulder, elbow and wrist joints mechanically, the wiring harness (electrical cabling) accomplishes the same thing only electrically. The wiring harness provides electrical power to all the joints and the End Effector (mechanical hand) as well as data and feed back information from each of the joints. This link continues from the SRMS in the payload bay and continues on into cabin of the space shuttle where astronauts control the actions of the arm remotely.

. The Canadarm's end effector (Spar) END EFFECTOR

The End Effector or mechanical hand of the SRMS allows the arm to capture stationary or free flying payloads by providing a large capture envelope (a cylinder 20.3 cm in diameter by 10 cm deep) and a mechanism/structure capable of soft docking and rigidizing. This action is accomplished by a two stage mechanism in the End Effector which closes three cables (like a snare) around a grapple probe (knobbed pin) bolted onto the payload and then draws it into the device until close contact is established and a load of approximately 499 kg is imparted to the grapple probe. The forces developed by the End Effector on the payload through the grapple probe will allow for manoeuvring of the payload without separation from the remainder of the SRMS to the positional accuracy’s previously stated.

CLOSED CIRCUIT TELEVISIONS (CCTV)

The SRMS has two CCTV’s, one at the elbow joint and one at the wrist joint. The CCTV units are used to aid the astronauts in the positioning of the arm for payload capture/retrieval or payload by capture/deployment.

. Working with the Canadarm (MDRobotics) SRMS CONTROL SYSTEM

The movement of the SRMS is controlled by the space shuttles general-purpose computer (GPC). The hand controllers used by the astronauts tell the computer what the astronauts would like the arm to do. Built in software examines what the astronauts commanded inputs are and calculates which joints to move, what direction to move them in, how fast to move them and what angle to move to. As the computer issues the commands to each of the joints it also looks at what is happening to each joint every 80 milliseconds. Any changes inputted by the astronauts to the initial trajectory commanded are re-examined and recalculated by the GPC and updated commands are then sent out to each of the joints. The SRMS control system is continuously monitoring its “health” every 80 milliseconds and should a failure occur the GPC will automatically apply the brakes to all joints and notify the astronaut of a failure condition. The control system also provides a continuous display of joint rates and speeds, which are displayed on monitors located on the flight deck in the orbiter. As with any control system, the GPC can be over-rided and the joints can be operated individually from the flight deck by the astronaut.

THERMAL PROTECTION SYSTEM

The SRMS is covered over its entire length with a multi-layer insulation thermal blanket system, which provides passive thermal control. This material consists of alternate layers of godized Kapton, Dacron scrim cloth and a Beta cloth outer covering. In extreme cold conditions, thermostatically controlled electric heaters (resistance elements) attached to critical mechanical and electronic hardware can be powered on to maintain a stable operating temperature.

|

. |

| Canada's arm in the sky (NASA) |

TECHNICAL DETAILS

Length: 15.2 m (50 ft)

Diameter: 38 cm (15 in)

Weight on Earth: 410 kg (905 lbs)

Speed of Movement: 60 cm/sec (2 ft/sec) when free, 6 cm/sec (2.4 in/sec)

when loaded

Upper & Lower Arm Boom: Carbon Composite Material

Wrist Joint: Three degrees of movement (pitch/yaw/roll)

Elbow Joint: One degree of movement (pitch)

Shoulder Joint: Two degrees of movement (pitch/yaw)

Translational Hand Controller: Right, up, down forward, and backward

movement of the arm

Rotational Hand Controller: Controls the pitch, roll, and yaw of the arm

Reprinted courtesy of MacDonald Dettwiler Space and Advanced Robotics Ltd.