UNIQUE FLEXIBILITY

|

. |

| CANDU 6: Point Lepreau (AECL) |

CANDU is an acronym for CANada Deuterium Uranium. A unique design, the CANDU system uses deuterium oxide (heavy water) as moderator and natural uranium as fuel.

The core of the nuclear steam supply system of a CANDU 6 power plant is a large cylindrical vessel called the calandria. This vessel is filled with cool, low-pressure heavy water. The vessel houses 380 horizontal tubes, loaded with natural uranium fuel bundles.

With the uranium fuel surrounded by heavy water, chain reaction fission takes place, releasing energy in the form of heat. The heat is transferred to a second heavy water system pumped at high pressure through the tubes to steam generators. There its heat is transferred to ordinary water which boils to become the steam that drives the turbine generator.

PROVEN PERFORMER

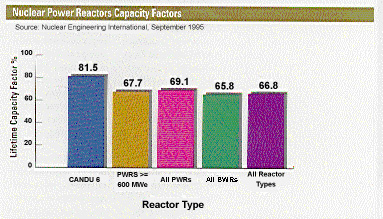

CANDU 6 reliability figures speak for themselves. According to the authoritative analysis in Nuclear Engineering International (NEI), the CANDU 6's capacity factor is consistently higher than all other types of reactors.

| . |  |

| CANDU 6: At The Top (AECL) |

The four CANDU 6 units have each achieved high reliability figures, even after 13 years of operation.

The lifetime capacity factor (CF) is the total gross generation (TGG) figure divided by the capacity (CF) divided by the total number of hours (hrs) from the time of first synchronization to that time, multiplied by 100. CANDU 6 units have the highest lifetime capacity factors within their class.

PROVEN SAFETY

|

. |

| CANDU 6: Safety First (AECL) |

Originally licensed in Canada, the CANDU 6 has also been licensed in every country where it has been sold over the past two decades. With Wolsong 2, 3 and 4, CANDU 6 met all requirements for licensing in both Canada and Korea, the latter having licensed both PWR and CANDU systems.

The regulatory bodies of other countries have accepted the Canadian licensing criteria and documents equivalent to those submitted for a reference plant in Canada. The Canadian regulator, the Atomic Energy Control Board (AECB), generally plays a role in the transfer of expertise to international regulatory bodies by providing licensing training courses, attachment of personnel and regular exchange meetings.

Part of the CANDU's licensing acceptability is its approach to safety. Long operating experience under a wide range of demanding conditions certainly bears this out. The unique CANDU 6 "defence-in-depth" design incorporates tri-level passiveness. Preventative boundaries and independent shut-down systems are built into the superior design, at multiple levels. Its advanced approach is proven with two decades of reliability data that reflect the importance of safety designs. Of note is the fact that CANDU has established an excellent long-term history in minimizing radiation doses to operating staff. This has contributed to ease of plant maintenance which, in turn, has contributed to operating reliability and lower operating costs.

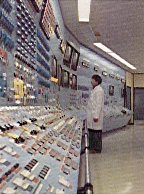

All CANDU 6 power plants are highly automated, requiring only a minimum of manual operator action. Each plant has two independent digital computers which operate continuously, one operating and one on standby. All aspects of the plant's operation are monitored and controlled from the control room. Here, a computer display system provides performance information in the form of graphs, bar charts, and printed records. Standard displays can be supplemented by additional information on operator request. Should the main control room not be available, the station can be shut down and kept in a safe condition from a secondary control room in another part of the plant.

The safety systems of CANDU 6 power plants include two independent and fully capable shutdown systems. To provide maximum safety, the systems are separated physically and functionally.

MODERATOR AND COOLING

The moderator operates at low pressure and temperature, completely separate from the primary heat transport coolant circuit, providing a huge body of water capable of absorbing excess heat if a major accident should occur. Among other safety features in CANDU power plants are the emergency core cooling system and the containment system. In the event of a loss-of-coolant accident, the reactor safety systems will shut down the reactor, isolate the defective primary heat transport coolant circuit, and assure a supply of cooling water over the fuel. Multiple containment consists of several systems and structures that provide sealed barriers around nuclear components to prevent the release of radioactivity. CANDU's many safety systems are the embodiment of a world leading defence-in-depth design philosophy.

CLEAN AND ENVIRONMENTALLY BENIGN

| . |  |

| CANDU 6: Environmentally Sound (AECL) |

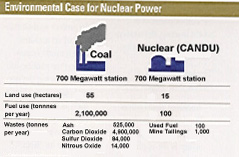

A CANDU 6 produces about 24 cubic metres of used fuel bundles per year, a volume that would fit into a small room. The design of the CANDU 6 power plant is such that these wastes are strictly controlled and represent no threat to station personnel or to the public.

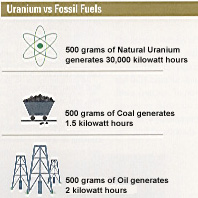

The 700 MWe class CANDU 6 nuclear power plant saves the burning of about 84 million tonnes of coal or about 330 million barrels of oil over a 40-year period and the millions of tonnes of acid-producing atmospheric pollutants these fossil fuels would generate. A CANDU 6 also avoids the release of 196 million tonnes of carbon dioxide over its lifetime, an amount that would be produced by a fossil-fuelled plant of equal size.

|

. |

| CANDU 6: The Better Choice (AECL) |

Other environmental highlights include:

1) Air and water discharges from CANDU 6 stations are free of such contaminants as heavy metals, organic compounds and acid gases. Radioactivity releases in any form are closely monitored, and are consistently less than 1% of those permitted by regulatory standards.

2) CANDU 6 stations occupy relatively little land since space is not required for large coal storage and ash disposal areas.

3) The CANDU 6 at Point Lepreau produces about 300 kilograms of used fuel per day. An equivalent coal-fired station produces eight tonnes of fly ash and 1440 tonnes of solid ash a day.

WASTE MANAGEMENT UNDER CONTROL

AECL is a world leader in developing safe technology for the handling and storage of spent fuel from nuclear reactors. The overall philosophy and strategy, which has been the subject of 50 years of continuing research and development, is to provide interim storage at the reactor site, followed by permanent disposal underground in geologically stable formations.

Used nuclear fuel has been stored in water-filled pools at CANDU nuclear generating stations for 25 years and can be stored in this way for many decades. The use of concrete canisters for "dry storage" of used CANDU reactor fuel is now coming into wide use because it provides safe storage at lower cost than water-filled storage pools. At the Point Lepreau plant, for example, after at least seven years under water, the spent fuel (which has seen a decrease in radioactivity of about 99 percent) is moved to on-site dry-storage canisters, where each year's discharge fills about 10 canisters.

AECL has recently developed the MACSTOR above-ground dry storage system for spent CANDU fuel, as well as fuel from other reactor types (PWR, BWR and VVER).

It features superior cooling and shielding, easy fuel retrievability for future off-site disposal, resistance to earthquakes and tornadoes, and exceptionally low construction and operating costs. A MACSTOR unit was installed in a record five and a half months at Hydro Quebec's Gentilly-2 CANDU station in 1995.

SUCCESS FOR TOMORROW

| . |  |

| CANDU 6: The Future Calls (AECL) |

The CANDU 6 has evolved over the past 20 years into a proven design with high reliability and worldwide customers. As more CANDU 6 units enter service, operator and customer feedback will continue to be the major contributions to CANDU 6 evolution. This will ensure that improvements are defined by those best suited to make this judgment, the owner-operator.

In the future the CANDU 6 will continue to evolve as AECL incorporates

technological updates, again through a continual process of review with the CANDU 6 family of utilities.

The CANDU 6 will remain a world leader in terms of reliability and power production. And as it continues to incorporate the latest operating systems while meeting the increasing demands from its international customers, this proven work-horse will continue its success well into the next century.

Reprinted courtesy of AECL Ltd.