By: R. Brewer, PhD, P.Eng.

E.D. Hallman, PhD

K.R. Langille, P.Eng.

K. McFarlane, P.Eng.

P.H. Oliver, P.Eng.

Unique challenges in engineering and science have been met in the construction of the Sudbury Neutrino Observatory

The availability of a deep underground site, heavy water from Canada's stockpile, and the necessary teams of scientists, engineers and construction personnel have enabled Canada to host a world-class observatory for the study of neutrinos-elusive yet fundamental building blocks of matter.

The site, provided and serviced by Inco Limited on the 2073-metre level of the Creighton Mine near Sudbury, Ontario, and access to 1000 tonnes of heavy water from AECL stockpiles for Canada's CANDU power reactors (with the cooperation of Ontario Hydro) are unique resources for this $70-million facility, now close to completion.

The unique design feature of the observatory is its 1000-tonne heavy water core enclosed inside a 12 metre acrylic plastic vessel and surrounded by 8000 tonnes of ultrapure ordinary water in a 22m-diameter by 34m-high cavity.

Designed and constructed by a 65-member collaboration of scientists from 13 institutions in Canada, the United States and Great Britain, the Sudbury Neutrino Observatory (SNO) is funded by Canada's Natural Sciences and Engineering Research Council, The National Research Council Canada, The U.S. Department of Energy, Industry Canada, The Northern Ontario Heritage Fund, Inco Limited and the Particle Physics & Astronomy Research Council of Great Britain. Project management is provided by Agra-Monenco/Canatom.

Engineering challenges have been present at every phase of this project, from the geotechnical design of the huge cavity in the high-stress environment deep underground, to the mining engineering for the excavation, the unique structural engineering for the cavity deck, the component suspension systems and the one-of-a-kind acrylic vessel.

The underground location in the busy Creighton mine with its limited access, as well as stringent requirements for high-purity materials and water and cleanroom assembly of the detector, all posed additional challenges. Teamwork of engineering groups, SNO scientists and Inco operations personnel was essential. Quality control of every step of the assembly process was a top priority.

Following are some examples of the wide spectrum of engineering challenges posed and the solutions achieved.

Solving the Solar Neutrino Problem

Neutrinos are fundamental building blocks of matter-along with photons they are the most numerous particles in the universe. Huge numbers of neutrinos produced in the "big bang" origin of our universe still travel through it, after 15 billion years. Our sun is an excellent nearby neutrino source. Only four other underground laboratories around the world have solar neutrino detectors.

The SNO detector uses 1000 tonnes of "heavy water" or D2O in a spherical acrylic tank as the neutrino sensor. Tiny flashes of light emitted, as neutrinos are stopped or scattered in the tank, are detected by 10.000 light sensors which surround the central heavy water.

The SNO experiment is of great interest to neutrino scientists because the SNO detector is the first one with the capabilities of seeing all three species of neutrinos, to check a theory that neutrinos can change from one species to another on their to us way from the sun. This theory could explain the "solar neutrino problem"-a disagreement of current measurements of neutrinos from the otherwise-good theory of how the sun works.

The SNO detector will be sensing tiny amounts of light (equivalent to a light bulb flask from the moon), and should see about 20 neutrino "events" each day. Even tiny amounts of radioactivity from the components, water or dust in the detector could interfere with or block neutrino signals. Clean assembly of ultrapure components, and a state-of-the-art water purification and monitoring system are required.

Geotechnical and Mining Challenges

|

. |

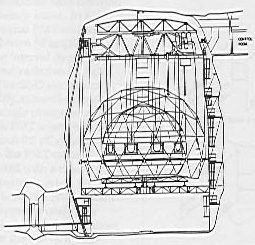

| Above: An engineering cross section drawing of the partially-completed detector (SNO) |

The SNO detector required a vertical cylindrical cavity 22m in diameter by 34m high, in a site with at least 1500m of rock cover, to eliminate cosmic ray backgrounds.

A location on the existing 6800 level (2073m) at Inco's Creighton mine outside the region of mining influence was selected. An exploration tunnel was driven in 1986, to a site in the hanging wall norite rock-a uniform, good-quality rock with low background radioactivity-and rock stresses and properties were measured. The design and excavation of the cavity and access drifts began in 1990. Numerical modeling used to select optimum cavity and entry tunnel shapes, the design of the wall support system. Extensometers, stress cells and camera inspection holes were installed near the cavity from three stations around the cavity prior to its excavation.

The cavity dome was excavated at the 2073m level, and o driven to the bottom centre of the cavity. A central 3m-diameter slot was crater-blasted up to the dome. The cavity was excavated downward in six bench blasts, with excavated rock dumped down the slot, removed by scooptram up the ramp and trammed to the mine skip for transport to the surface. During the excavation process, 40,000 tonnes of rock were removed from the cavity.

Four reinforced concrete corbels for the cavity deck structure were installed using post-tensioned cables grouted 20m deep into the surrounding rock mass, after the first bench was excavated. The permanent ground support system, consisting of 2.4m grouted rebar rods at 1 m centres, holding #4 welded wire mesh screen, was installed as the cavity was excavated. Seismic support was provided by double 16mm-diameter cement grouted cable bolts, 7.6m long, with centres at 1.1m for the cavity roof and 1.5m for the walls. A 7.5cm-thick layer of shotcrete completed the support system. Rock monitors showed an initial small convergence of cavity walls as the excavation proceeded, and negligible change in wall conditions since that time.

Construction Engineering Challenges

The scale of the SNO experiment imposed numerous challenges on the construction team, starting with the need to create an air-conditioned laboratory with a floor area of 1200m2 (and volume 12,000m2) 2 kilometres underground in an operating mine with its production priorities. Materials and equipment for the laboratory had to be transported on Inco-style mine cars, down the shaft in a two-level mine cage, then trammed a further 1.5 km around the active mining area to the SNO site. Construction engineering began with the design of a deck for the cavity at the floor level of the top entry tunnel, which would support the acrylic vessel and light sensor sphere for the detector. The two main support trusses installed after the first cavity bench blast, were utilized to move drilling, blasting and slushing equipment into and out of the cavity as the lower rock benches were removed. To provide access to all parts of the cavity during construction, an 18m diameter platform (with an 80-tonne capacity and 25m lift range) was installed, lifted by 10 powered hoists anchored directly to the rock walls. Using this platform, the trusses were completed and a reinforced concrete deck installed.

| . |  |

| Above: A D2O tanker car is prepared for heavy water transfer in the SNO laboratory (SNO) |

In the next phase of cavity construction, a wall drainage system and a second layer of shotcrete were applied and trowelled to form a continuous smooth surface. A 7.5mm-thick coating of polyurethane (Urylon Plastics Incorporated Mineguard) was sprayed on the finished walls and floor of the cavity and the underside of the deck as a water and radon gas barrier. A new x-ray coating thickness probe was used in an inspection program to ensure thickness and integrity of the coating.

While the cavity construction was taking place, services for the rest of the laboratory were installed, including water, forced drains, compressed air, instrument air, lighting, ventilation and air conditioning, a communications system and a fire detection and control system. Notable challenges in this work were the installation of a 4km, continuous (2x6) fibreoptic cable from the surface operations control building down the shaft and to the laboratory, the design and installation of a 125-tonne double compressor chiller system at an existing mine exhaust shaft and the installation of a 75,000-litre bladder tank and pump for the fire protection system.

Acrylic Vessel and Light Sensor Support Structure

The acrylic vessel (AV), a 12m-diameter sphere designed to hold 1000 tonnes of heavy water (10% heavier than ordinary water), is suspended in the centre of the SNO cavity, partially supported by the pure ordinary water that fills the rest of the cavity. The size, location and function of this vessel are major engineering challenges for the SNO project. The weight of the vessel in air and during detector operations requires 100 tonnes of support from the suspension ropes, making the vessel a major structure. The vessel must be extremely low in radioactive contaminants and have excellent optical transparency for the tiny light flashes from neutrino events. Noncrosslinked acrylic, manufactured by Polycast Limited, was chosen as best meeting these requirements. Since the mineshaft cage dimensions restricted acrylic panels to a maximum size of 2m x 3m, the AV had to be bonded together on site from 130 individual components. The assembly and bonding process had to provide for bond shrinkage during the exothermic curing process to avoid locking in residual stresses higher than normal operating levels. In addition, to control heat generation during bonding, the 3mm bond gaps between panels had to be controlled to a tolerance of ± 1.5mm. Because acrylic has a relatively large expansion coefficient, the 55mm thick panels were first thermoformed to a spherical 6m radius, then machined (at a constant design temperature) on a numerically controlled mill at the facilities of prime vessel contractor, Reynolds Polymer Technology of Grand Junction, Colorado.

During detector operation, the level of the heavy water in the chimney of the AV is controlled so that the sphere is under an external compression ranging from zero at the bottom (south pole) to nearly 14 kilopascals at the top of the sphere. The geometry of the sphere is controlled to ± 6mm on the 6m radius using a theodolite system, to provide a large safety margin against buckling.

The vessel was constructed one horizontal ring at a time, beginning with the equator panels, which also included thicker panels for the 10 grooves for the vessel support ropes. Following vertical bonding of all panels in the ring, a single pour of bond syrup was made to join the next ring to the existing vessel. When the upper hemisphere was complete, a 1.5m chimney was bonded to the top, and the vessel was suspended on its support ropes. The construction platform was then lowered, and rings of panels were installed below the equator, ending with a south pole cap. The support ropes, were specifically fabricated by Yale Cordage Limited, from Vectran, a polymer with excellent resistance to ultrapure water.

The ABS plastic panels supporting the 10,000 20cm-diameter light sensors (or photomultiplier tubes), and the 16m stainless steel geodesic sphere in which they are mounted, were designed and supplied by Lawrence Berkeley Laboratories in California. The upper hemisphere of the light sensor sphere and its panels were installed first in the cavity, using a polar crane suspended from the cavity deck, and a hoist through the central opening in the deck. The lower hemisphere will be installed in three sections as the corresponding AV sections are completed.

Water Purification

The water used in the SNO detector must be extremely pure to minimize back-ground to the neutrino measurements from trace radioisotope contaminant. Separate systems for heavy (D20) and ordinary (H2O) water have been installed in the laboratory. Eight thousand tonnes of ultrapure H20 will be produced from the mine water supply, for filling the outside portion of the cavity. Conventional systems (filtration, softeners, charcoal filters) are used to supply water to a high-recovery reverse osmosis system by Sepratech Systems. Permeate, typically 1.5 muS/cm, is directed to a 10-tonne polypropylene holding tank for use as make up. The circulating H20 loop includes a canned pump, two-stage ion exchange bottles producing 0.054 muS/cm water, ultraviolet sterilizers, a vacuum degasser, particle filters and a heat exchanger.

Radon from the rock in the under ground environment is at quite a low level, but it is a potentially serious water contaminant for the SNO detector. An efficient radon removal system is used to reach target levels of radon in equilibrium with its uranium or thorium sources at a level of one part in 1014. A packed-bed degasser with vacuum pump, heater and condenser coil is used to achieve oxygen reduction levels in the H20 greater than 99.95% at flow rates of 135 litres per minute, with a vapour load of 0.03 litres per minute. Radon reduction through this degasser is expected to be greater than 98%.

Heat removal from the H20 is achieved using a separate system with a heat exchanger and ultrafiltration unit. This loop will maintain cavity water at about 10° C with a minimum of convection currents. A nitrogen cover gas system (generated by boil off from liquid nitrogen) will provide a barrier to radon.

Target purities for the D20 are 10 times more stringent than for the H20. In addition, losses of D20 must be minimized and contamination with H20 must not occur. During operations, two tonnes of magnesium chloride will be periodically cycled in and out of the D20 as part of the neutrino detection program. This cycling is achieved through a separate reverse osmosis system that concentrates the salt into 6% brine, stored in a 60 tonne holding tank when not required. Potential contamination of the ultrapure water was minimized by the use of specially produced polypropylene pipes and fittings (by Fabco Plastics and Caledonia Plastics). Where necessary, Hastelloy (a high-nickel-content alloy) or titanium components were used. Circulation pumps are either magnetically coupled or incorporate double seals with an intermediate fluid to act as a radon barrier.

Materials and Cleanliness Requirements

Because many materials contain minute amounts of natural radioisotope impurities that could interfere with the neutrino measurements, there are stringent requirements for the materials in the core of the detector. As a consequence, materials and components for SNO have been specially prepared from sources all over the world. For example, a limit of one part in 1012 for impurities in the acrylic of the heavy water vessel required special production techniques and development of state-of-the-art monitoring techniques. A limit of no more than 50 grams of equivalent mine dust on all inner surfaces of the detector has led to the adoption of cleanroom conditions for the assembly work in the cavity. Six air handier units provide cooling, humidity control and three levels of filtration for incoming air to the laboratory- For the past 2.5 years, an average CLASS 3000 (particles per cu.ft. greater than 0.5 microns in size) has been maintained for laboratory air. Personnel must shower and change to cleanroom clothing on entering the laboratory and operations are governed by cleanroom procedures. An extensive cleaning and monitoring program is also in place, including the use of a unique x-ray fluorescence technique pioneered for SNO to check for residual dust on component surfaces.

Challenges Met

As the assembly of the SNO detector nears completion in 1997, many scientific and engineering challenges have been met. Communications links and most laboratory systems, including an extensive controls monitoring and alarms system, are in place. With the aid of a contribution from Northern Telecom in Ottawa enabling the production of a vital electronics chip for the detector, the SNO electronics system is nearing completion. Many SNO institutions have developed the computer systems and software for data collection and analysis.

Although the seven-year operations period will no doubt bring new challenges, the SNO experiment is a tribute to the unique international collaboration of finding agencies, supporting companies, scientists, engineers and constructors. With its potential for answering fundamental questions about neutrinos, our sun and the universe, SNO should continue to hold much world-wide interest for years to come.

Robert Brewer, PhD, P.Eng., is a project manager, Agra-Monenco/Canatom Ltd. Doug Hallman, PhD, physics professor, Laurentian University, is director of communications, Sudbury Neutrino Observatory. Kenneth Langille, P.Eng., is a project coordinator, Inco Limited. K. McFarlane, P.Eng., is with the Centre for Research in Particle Physics. Philip Oliver, P.Eng., is in the Mines Research department, Inco Limited.

Reprinted courtesy of Engineering Dimensions