(1) |

1 Graduate School of Medical Sciences, Kyushu University, Fukuoka, 812-8582, Japan

2 Kyushu University Hospital, Fukuoka, 812-8582, Japan

3 Faculty of Science and Engineering, Saga University, Saga, 840-8502, Japan

Electromagnetic interference (EMI) with electronic medical equipment is a problem of increasing concern. Although there is the possibility of EMI by a static magnetic field, no safety standards for electronic medical equipment have been formulated. We measured the magnetic flux density of our hospital building, which is constructed with a steel frame. We also investigated EMI with a digital electrocardiograph, an analog electroencephalograph, and four types of monitor displays.

Strong magnetic flux density, exceeding 200µT, was observed at the welds of deck plates, at the piping holes of metal deck plates, and at the welds of metallic ornaments hanging from the deck plates. Magnetic flux density changes greatly with slight differences of probe location. EMI was observed on a CRT, but not on a LCD, a color TFT, a PDP, or the medical equipment.

In this study, a static magnetic field was confirmed to cause EMI with a CRT, which is an integral part of some electronic medical equipment. Hospitals would benefit from residual magnetic field measurement to protect patients from EMI. De-magnetizing or magnetic shielding would help prevent EMI.

Keywords: electromagnetic interference, static magnetic field, residual magnetization, electronic medical equipment, display monitor

Electromagnetic interference (EMI) with electronic medical equipment is a problem of increasing concern. EMI by electromagnetic field radiation (radio waves) has been reported [1-3]. Compatibility and immunity standards for electronic medical equipment against radiated electromagnetic fields have been issued internationally [4]. However, there are no reports of EMI by a static magnetic field. Although the possibility of EMI with electronic medical equipment, such as an artificial-heart pacemaker, by static magnetic fields has been reported [5], no safety standards for electronic medical equipment have been formulated.

In this study, we investigated EMI by static magnetic fields by measuring residual magnetization at electric welds, possible sources of static magnetic fields, in our steel structured hospital building.

A new building at Kyushu University Hospital has 11 above ground floors and one basement floor. The steel framing had been completed, and the interior finish work was being done at the time of testing. We measured magnetic flux density in the emergency treatment room, intensive care unit, coronary care unit, and recovery rooms, rooms in which a number of pieces of electronic medical equipment would be installed. Magnetic flux density measurement was done 100 mm and 1,000 mm above the floor at each corner of a 1 m grid drawn on the floor of each room measured.

A Gauss meter (HM-320, MTI Co.) and a 3-axis probe (attachment HM-320, MTI Co.) were used. A 3-axis probe with a Gauss meter can measure the magnetic flux density in 3 axial directions simultaneously using the magnetic dispatch system. The measurable range of the Gauss meter is from -200µT to +200µT. Accuracy is 100 nT for each direction.

The magnetic flux density Fe at each point measured was calculated by the following equation (1).

(1) |

where, Fx, Fy, Fz are the magnetic flux densities obtained by the Gauss meter for the three directions.

Measurement was done on a holiday when there was no construction activity. The weather was cloudy.

At each point of highest magnetic flux density measurement, we determined if EMI occurred with a digital electrocardiograph (ECG-9020, Nihon Kohden Co. Ltd.) including a monochrome liquid-crystal-display (LCD) monitor [6], and with an analog electroencephalograph (EEG-7414, Nihon Kohden Co. Ltd.). The electrocardiograph was placed on the floor when testing, and a person acting as a patient lay on a plastic bench 400 mm from the floor. The electroencephalograph was on a wagon at a height of 1,000 mm with the same person sitting on the plastic bench during testing.

For both pieces of electronic medical equipment, a skilled clinical engineer carefully attached sensors to the person. Sensor noise was decreased to the minimum. Both the electrocardiograph and the electroencephalograph were electrically grounded to reduce noise from the exchange power supply to a minimum.

We tested whether or not color distortion would arise in a television cathode-ray tube (CRT) display by playing a video tape from a television with a built-in video player. We also tested 2 digital patient monitors (M3000A and M1205A, Agilent Technologies Ltd.) with color liquid crystal displays that used thin-film transistors (TFT) monitor [7]. Each monitor was operated in test mode. A 42-inch plasma display panel (PDP) [8] (Flexscan P4260, Eizo) attached to a personal computer and a digital patient monitor were also tested. A mono-color image, a picture image, and animation were displayed, and distortion and color change on the display were observed by three persons. These observations were done at the point of highest magnetization in the emergency operation room on the first floor and in a recovery room on the seventh floor.

|

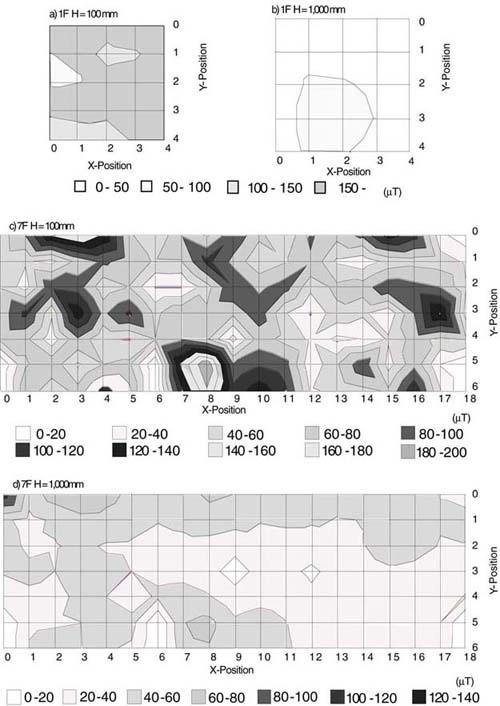

Fig.1. Magnetic flux density distribution

|

Two examples of measurement results are shown in Fig. 1. Values on the X and Y axes show the distance of the measurement point from the wall, and the value on the Z axis shows the magnetic flux density. Magnetic flux density changes greatly with slight differences of probe location. Especially strong magnetic flux density was observed at the welds of deck plates, the piping holes of metal deck plates, and the welds of metallic ornaments hanging from the deck plates. Strong magnetic flux density was also observed close to the following points; aluminum sash frame to metallic wall structure welds, the welds of steel girders to each other, and welds of the metal frames in partition walls.

|

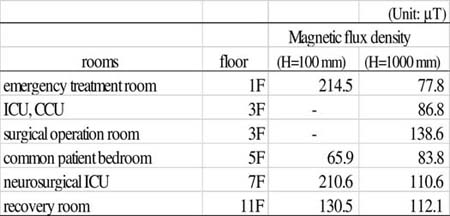

Table 1. Maximum magnetic flux density at each observation point |

The maximum magnetic flux density observed at each measurement point is shown in Table 1. Strong magnetic flux density was observed on every floor. The magnetic flux density exceeded the range of the Gauss meter at 100 mm above the first and seventh floors. The magnetic flux density 100 mm above the floor was higher than at 1,000 mm above the floor at most of measurement points. For example (see Figs. 1c and 1d), the maximum magnetic flux density measured in the recovery room on the seventh floor was 210.6 µT at 100 mm above the floor and 110.6 µT at 1,000 mm above the floor.

No EMI was observed with the electrocardiograph or the electroencephalograph. No noise was observed on either piece of equipment. Monochrome LCD, TFT monitor, and PDP showed no distortion or color change. However, color change was observed in the television CRT at measurement points where strong magnetic flux density was observed. The color change was different as the position of the television changed. For example, blue on the CRT became red or green with very slight differences in the location of the television. The color change was not seen over the whole screen, but was partially changed or parts of the screen changed with changes of location. The color change lessened as the television was moved to higher positions.

Because of the strong magnetic flux measured, it was expected that the electroencephalograph placed 1,000 mm above floor and the electrocardiograph placed on the floor would experience EMI. However, no EMI was observed for either.

For the electrocardiograph, since the direction of the magnetism was fixed in the static magnetic field, the magnetism filter (de-gauss filter) possibly protected it from EMI. For the electroencephalograph, the pen driver coils, which tend to be easily interfered with by magnetism, were in a position 1,000 mm above the floor, a sufficient distance to fully protect it from EMI from the weak magnetic flux density found 100 mm from the weld.

EMI with the CRT was observed, but none was observed with the LCD. The direction of CRT beams is changed by magnetic power from two magnetism deviation coils. The beams make a fluorescent material luminous. Therefore, when magnetic flux density is strong, magnetism is forced in a direction different from that of the magnetism deviation coil, and color change or distortion appears. The liquid-crystal elements of an LCD would not change direction unless very powerful magnetism was radiated. The source of light for the monochrome LCD used in the observation was external light reflected in a mirror in the back of the screen. A LCD does not use a deviation coil. Theoretically, LCDs should be little influenced by magnetism.

|

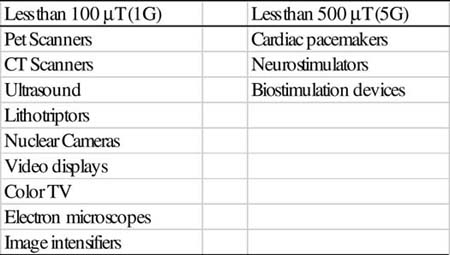

Table 2. Equipment typically susceptible to various static magnetic field levels as reported by GE Medical Systems |

In the case of static magnetic fields, magnetic flux density is in inverse proportion to the square of the distance from a magnetized point. Therefore, it is possible to prevent EMI by keeping electronic medical equipment away from the magnetized weld. When equipment cannot be placed far enough from a weld, de-magnetization [9-10] or shielding may be necessary. De-magnetization can negate the magnetic energy by emitting the same volume of magnetic energy in a reverse direction to every magnetized point, after investigation of magnetic energy and its direction. However, when there are large numbers of magnetized welds, de-magnetization requires much time. Magnetic shielding, such as highly permeable materials, permalloy, silicon plate, and amorphous metal can be used to protect electronic medical equipment from magnetism. However, highly permeable materials are expensive. One standard for safe performance in cases where magnetic flux density is over 80µT (0.8 G), the standard for CRT [11], is placement from 100 mm to 300 mm above the floor. This is considered the lowest safe installation height for general electronic medical equipment. GE Medical Systems has published a Proximity Limit Chart for their MRI systems that indicates equipment typically susceptible to various static magnetic field intensities. Examples are shown in Table 2.

In this study, a static magnetic field was confirmed to be the cause of EMI with a CRT, which is an integral part of some electronic medical equipment. The residual magnetization of welds in a hospital should not be overlooked. Near the electric welds of steel frames and deck plates, strong residual magnetic flux density, which may produce EMI with electronic medical equipment, was found. Therefore, it would be beneficial for hospitals to do residual magnetic-field measurement and to place electronic medical equipment away from strongly magnetized points when strong magnetic fields are found. De-magnetization or magnetic shielding would be helpful for the prevention of EMI.

The authors wish to deeply thank Nihon Kohden Co. Ltd. and Agilent Technologies, Japan, Ltd. who provided the electronic medical equipment and displays. This research was supported by grants-in-aid from the Japan Society for the Promotion of Science (No.12771451).

1. Anonymous. "Radiofrequency Interference with Medical Devices," IEEE Engineering in Medicine and Biology Magazine 17(3); pp.111-114, 1998

2. Dwyer D. "Medical Device adverse events and electromagnetic interference," Intl. J. Trauma Nursing 5(1); pp.19-21, 1999

3. Electromagnetic Compatibility Conference "Research Report of the usage of Radio-communication Equipment such as Cellular Telephone Handsets," Association of Radio Industries and Business, Tokyo, 1997

4. International Electrotechnical Commission. International Standard "IEC 60601-1-2 Medical Electrical Equipment Part 1: General Requirements for Safety 2.Collateral Standard: Electromagnetic Compatibility Requirements and Tests," Geneva, Switzerland: International Electrotechnical Commission, 1993

5. Ministry of Health and Welfare, Pharmaceutical and Medical Safety Bureau (Japan) "Information on Adverse Reactions to Drugs," No.155 (3), 1999

6. Sharp Corp. "The Structure of Simple/Active Matrix Drive Systems," In their WebPages (https://sharp-world. com/sc/library/lcd_e/s2_4_3e.htm), 2000

7. Sharp Corp. "Defining the New LCD Age with New LCD Technology," In their WebPages (https://sharp-world. com/sc/library/lcd_e/s2_5_1e.htm), 2000

8. Sharp Corp. "Plasma Display Panels (PDP)," In their WebPages (https:// sharp-world.com/sc/library/lcd_e/ s2_6_2e.htm), 2000

9. Ishikawa N., Kajiwara G., Okada A., and Inubushi A. "Degaussing method for the structural materials in the building," Tech. report of IEICE (Japan), EMCJ99-136, 2000

10. Kajiwara G., Ishikawa N., and Inubushi A. "Development of the demagnetizing device for reinforcing bars in the building," Proc. of the Japan Construction Society Annual Conference, pp.1203-1204, 2000

11. "JEIDA-63 Standard for operating conditions of industrial computer control system," Japan Electronic Industry Development Association, Tokyo, Japan, 2000

|

Eisuke Hanada was born in Tokyo, Japan, in 1963. He received his B.Eng. and M.Eng. degrees from Kyushu University, Fukuoka, Japan, in 1985 and 1987 respectively. He received his D.Eng. degree from Saga University, Saga, Japan, in 2001. He worked for NEC Corp. for five years developing speech coding/decoding systems and at Nagasaki University Information Science Center for four years managing the campus LAN and information servers. Since 1996 he has been working at the Department of Medical Information Science, Kyushu University Graduate School of Medical Sciences. His research involves the wired/radio communication environment and information processing systems in hospitals. Dr. Hanada is a member of the Japanese Society of Medical Informatics, the Information Processing Society of Japan, and the Acoustical Society of Japan.

|

Kyoko Takano was born in Fukuoka, Japan in 1970. She received her B.Econ. and M.Info. de-grees from Teikyo Heisei University, Ichihara, Japan, in 1996 and 1998, respectively. She has been a research resident at the Department of Medical Information Science, Kyushu University Graduate School of Medical Sciences since 1998. Her research interest is the electromagnetic environment of hospitals and educational methods for nursing school students. Ms. Takano is a member of the Japanese Society of Medical Informatics.

|

Hiroyuki Mishima was born in Fukuoka, Japan, in 1972. He graduated from Fukuoka College of Medical and Dental Technology, Fukuoka, Japan, in 1994. He was licensed as a Clinical Engineer in 1994. He has been working in the Surgical Operation Center at Kyushu University Hospital since 1994, after a half year working at the Medical Engineering Center at Kyorin University Hospital. He operates and maintains life-support systems. His research interests are medical engineering for patient safety, hospital infection control, and hospital architectonics and facilities. Mr. Mishima is a member of the Japanese Society of Medical Instrumentation, Japanese Association for Operative Medicine.

|

Kenji Kodama was born in Fukuoka, Japan, in 1954. He received his MD and Ph.D. degrees from Kyushu University, Fukuoka, Japan, in 1978 and 1986, respectively. He is currently an associate professor at Kyushu University Hospital and a deputy director of the promotional office for the construction of the new Kyushu University Hospital. His research interests are anesthesiology, pain, and architectonics and facilities in hospitals. Dr. Kodama is a member of Japan Society of Anesthesiologists.

|

Yasuaki Antoku was born in Fukuoka, Japan, in 1970. He received his B.Eng. from Kyushu Institute of Technology, Fukuoka, Japan, in 1996. He is currently working at the Depart-ment of Medical Information Science, Kyushu University Graduate School of Medical Sciences. He is researching hospital LAN systems and is managing internet servers.

|

Yoshiaki Watanabe received his D.Eng. degree from Kyushu University, Japan, in 1978. He has been an assistant at Kyushu University, a lecturer at Kyushu University Hospital, and an associate professor at Saga University, Japan. Since 1990, he has been professor of the Department of Information Science at Saga University. His research interests are in the fields of neural networks and biomedical engineering.

|

Yoshiaki Nose was born in Fukuoka, Japan, in 1944. He received his MD and Ph.D. degrees from Kyushu University, Fukuoka, Japan, in 1969 and 1973, respectively. He is currently professor and chairman of the Department of Medical Information Science, Kyushu University Graduate School of Medical Sciences and the Medical Information Center at Kyushu University Hospital. Dr. Nose is an executive committee member of the Japanese Society of Medical Informatics.